Overview ITE

Since our founding in 2007, we’ve pioneered the development of our own equipment tailored for low-temperature logistics. Leveraging the high-performance cold insulation material “IceBattery,” we ensure temperature integrity and quality without relying on any power source during the transportation of food and pharmaceuticals. Our comprehensive solutions encompass the entire environmentally friendly cold chain, ensuring uninterrupted freshness and quality throughout the production, transportation, and consumption processes of fresh foods, medicines, and more.

Over the past 16 years since its inception, our company has been introduced to around 250 private enterprises spanning logistics, transportation services, food-related industries, and the medical sector. Moreover, it has garnered interest from approximately 60 local governments across various regions and has established collaborations with five universities. Currently, we are in the initial stages of engaging with companies in India. Additionally, we are actively showcasing the efficacy of the Ice Battery through academic channels, including publishing research papers in collaboration with universities in Japan.

About Founder & CEO

Pankaj Garg is a highly accomplished entrepreneur and strategic professional with 34+ years of experience in product invention, development, manufacturing, and business development across diverse industries, including AI Robotics, IT, Semiconductors, Electric Products, Healthcare, Cold Chain Logistics, and Retail Food. With expertise in applied R&D, Engineering, and Marketing, he is a dynamic leader driving successful strategic initiatives with out of box thinking.

At Intel, he played a pivotal role in shaping global product strategy, expanding the Mobile Laptop Centrino project, and establishing the brand’s presence in international markets. His strategic vision solidified Intel’s position in Asia, Europe, and America.

In 2007, Mr. Pankaj founded Innovation Thru Energy Co., Ltd, (ITE) developing eco-friendly systems that set industry benchmarks. He also guided business strategy at VIASPACE Co., Ltd, introducing groundbreaking products sourced from prestigious institutions like NASA, CalTech, and JPL. During his tenure at Intel Corporation, Pankaj held senior executive positions from 1998 to 2007, spearheading global strategic initiatives in mobile technology and graphics, achieving an 80% market share.

Mr. Pankaj strategic approach stems from a professional background in engineering, development, and product marketing at CIRRUS LOGIC, Yasukawa Denki Co., Ltd, and Kobe Steel Co., Ltd. He is known for his problem-solving skills and commitment to innovation.

Originally from India, he holds a B.Tech degree in Computer Science & Engineering. With decades in Japan, he seamlessly integrates into the culture and holds an MBA from the esteemed American Fox Business School. Recognized for his contributions, Mr. Pankaj holds more than 30 key patents in semiconductors, renewable energy, Cold Chain Logistics, and preservation, showcasing his strategic mindset and passion for technological advancements.

IceBattery® Preservation System (IBPS) Growth

IceBattery® preservation system (IBPS) is a versatile solution that serves all modes of transportation, meeting the unique requirements of the food, science, retail, and medical industries. With a proven track record, it ensures efficient and dependable cold chain logistics. IBPS sets itself apart by offering real-time temperature and location tracking, empowering you with valuable insights for optimal logistics management. By combining sustainability and cutting-edge technology, it delivers eco-friendly and globally connected cold chain solutions.

Features of "IceBattery"

“IceBattery” is a high-performance cold storage material that uses a special cold storage liquid created by our company’s proprietary formulation. We asked a third-party organization in Japan to conduct an acute oral toxicity test using mice, and they determined that no toxicity was found.

By using an IceBattery frozen in a freezer with a special cold storage box or container, it is possible to maintain a temperature of -35°C ~ +25°C without power for long periods of time. By using different “IceBattery” plates depending on the appropriate temperature range of the products being transported and stored, the inside of the refrigerator is maintained at a constant temperature range.

Since it does not emit CO2, vegetables, fresh foods, vaccines that require special temperature control, blood, organs, etc. can be transported long distances by various means of transportation (rail, land, air, sea) safely and with consideration for the environment. It also eliminates the need for capital investment in refrigerated trucks, which were traditionally required for low-temperature transportation.

Moreover, unlike conventional cooling methods utilizing dry ice or compressors (which compress refrigerant), our technology does not emit CO2, making it environmentally friendly and compliant with PIC/S GDP* standards. With a focus on sustainable delivery solutions, in May 2022, we collaborated with pharmaceutical wholesaler “Alfresa Co., Ltd.” to jointly develop an electric vehicle for pharmaceutical delivery equipped with our innovative “IceBattery.” This initiative marked the beginning of demonstration experiments aimed at revolutionizing pharmaceutical logistics. Read More

*PIC/S GDP (Pharmaceutical Inspection Co-operation Scheme Good Distribution Practice): Standards for the distribution of pharmaceuticals under pharmaceutical inspection agreements and joint pharmaceutical inspection schemes.

IceBattery Electric Vehicle

Normal refrigerated and refrigerated vehicles run compressors during transportation, but doing this with electric vehicles results in poor fuel efficiency and shortened travel distance, so the market for low-temperature transportation vehicles has not spread. However, the newly developed electric vehicle will be able to travel approximately 300km by utilizing an “ice battery” (according to our research).

The logistics industry is approaching a major turning point in response to growing social interest in global environmental issues and vaccine transportation. In addition to responding to the SDGs to reduce food loss and CO2 emissions, expectations are also rising for DX to visualize the effects of initiatives and management status. Given this social background, we offer a new solution called “IB-trace,” an IoT solution that implements digital technology on the analog hardware “Ice Battery” to monitor product delivery status and temperature. doing.

Our company has acquired approximately 30 patents and design rights both domestically and internationally, and by leveraging the technological capabilities based on these, we aim to deliver health and happiness to the world through environmentally friendly low-temperature logistics.

1. Challenges We Aim to Address

The issue of cold chain disparities that prevent food and medicine from being delivered safely

Currently, approximately 2.5 billion tons of food is wasted annually around the world, which is thought to account for approximately 40% of the food produced worldwide *1 . On the other hand, it is estimated that there are approximately 800 million people suffering from hunger in the world *2.

Although the world produces enough food to feed the entire population, overproduction in developed countries leads to waste at the consumption stage, and emerging countries lack facilities for storing crops and infrastructure for low-temperature logistics. Food loss occurs due to insufficient food intake. In order to solve the problem of hunger, we believe it is important to build a logistics system that allows safe food to reach every corner of the world.

*1. Source: WWF – World Wide Fund For Nature “DRIVEN TO WASTE”

*2. Source: United Nations “Status of Food Security and Nutrition in the World (SOFI)”

In addition, in the medical field, appropriate temperature control is required to deliver medicines, and the spread of the new coronavirus has focused attention on temperature control during vaccine transportation. In emerging countries such as India and Africa, it is estimated that approximately 20 million infants are unable to receive immunizations due to a lack of access to vaccines, resulting in 1.5 million children dying each year*. Transporting vaccines and pharmaceutical products that require strict temperature control is not easy in countries with underdeveloped low-temperature logistics infrastructure.

*Source: Japan UNICEF Association ”Just one vaccine can save lives.”

Even within Japan, the cold chain system cannot be said to be sufficient. In 2021, hygiene management in accordance with HACCP *1 was made completely mandatory, but a survey by the Ministry of Agriculture, Forestry and Fisheries revealed that the smaller the sales scale, the higher the percentage of businesses that have not implemented it. *2 . Furthermore, in fields such as regenerative medicine, storage and transportation require extremely delicate management, which increases transportation costs. We believe that by building a system that allows ice batteries to be used in such fields, various markets and possibilities will expand.

We believe that our strength lies in our ability to eliminate global disparities in low-temperature logistics and quickly provide solutions to fields that require the establishment of low-temperature management systems.

*1. HACCP: A hygiene management method that attempts to ensure product safety by identifying and intensively monitoring important steps in the manufacturing process to prevent food poisoning bacteria and foreign matter contamination of products.

*2. Source: Ministry of Agriculture, Forestry and Fisheries “Results of a survey on the implementation status of hygiene management in line with HACCP in the food manufacturing industry (FY2021)

2. Solutions for Resolving the Problem

Aiming to improve and change awareness in the low-temperature logistics industry by popularizing “IceBattery” that can guarantee temperature and quality

◆ Maintaining the freshness of agricultural products and realizing long-term transportation

Traditional refrigerated vehicles and reefer containers* often lead to moisture loss and drying out of agricultural products due to the circulation of cold air by compressors. In contrast, “IceBattery” emits cold air slowly and evenly, preventing vegetables from drying out and maintaining their freshness.

Collaborative Research: In collaboration with the University of Tsukuba, we conducted a comparative freshness experiment using “IceBattery” cold storage boxes and an incubator. The experiment measured parameters such as weight loss, leaf yellowing, and vitamin C content of baby leaves. Remarkably, all indicators showed no significant difference between the “IceBattery” cold box and the incubator, known for precise temperature control.

Results: Weight loss, leaf yellowing, and relative vitamin C content were equivalent between the “IceBattery” cold box and the incubator.

These findings underscore the effectiveness of “IceBattery” in preserving the freshness and quality of agricultural products during transportation, paving the way for improved long-term transportation solutions.

*Reefer container: A container whose internal temperature can be adjusted by supplying power.

In India, a 20-foot hybrid “IceBattery” container was deployed to transport fruit, with a temperature sensor monitoring internal temperature changes throughout the journey. Remarkably, the container maintained a consistent temperature for approximately three days. Additionally, we meticulously examined the weight and appearance of the fruit upon loading and unloading, conducting a thorough comparison to assess changes. The results affirmed that the fruit arrived in a state that retained its freshness, underscoring the effectiveness of the “IceBattery” container in preserving product quality during transportation.

◆ Maintains a constant temperature without being affected by outside temperature

We have verified the IceBattery capability to maintain a consistent temperature over extended periods, even amidst fluctuating external temperatures during long-distance transportation.

In a vaccine transportation scenario via aeroplane, temperature sensors were strategically placed at 27 locations within the LD3 air container, continuously monitoring temperature variations throughout the 72-hour journey. Despite frequent opening and closing of the container at each stop, the internal temperature remained unaffected by external conditions, consistently maintained between 2°C and 8°C. This temperature control protocol enables us to confidently utilize air cargo for vaccine transportation from Tokyo to Okinawa every November.

Temperature Change Simulation

We conducted temperature change simulations to imitate the conditions experienced during international flights to diverse countries and regions with varying external temperatures.

◆ Mixed loading of different temperature zones is possible

Introducing the “IceBattery System” eliminates the need for purchasing refrigerated trucks or containers. Instead, low-temperature transportation and consolidated loading can be achieved by integrating existing trucks without temperature control capabilities with dedicated “IceBattery” cold storage boxes. This approach significantly reduces the burden of capital investment.

We have a proven track record of implementation across various sectors, including industry, government, and academia, encompassing over 250 companies in Japan, including more than 50 major corporations.

Moreover, by enabling consolidated shipments, we contribute to the expansion of logistics routes, both domestically and internationally, reaching rural areas and island nations where product delivery was previously challenging.

◆ Aiming to build a new cold chain and modal shift

“IceBattery” is a simple mechanism that simply freezes the plates, so no specialized knowledge is required to use it, and we are proud that it is a revolutionary technology that does not place a burden on the environment as it does not emit CO2 during transportation.

If you have an “IceBattery System” that incorporates an “IceBattery” into a container or a special cold storage box, you can immediately start transporting at low temperatures, eliminating the need for large-scale capital investment in refrigerated trucks and refrigerated trucks. We believe it is possible to reduce running costs because no electricity is required during transportation. We also believe that the IceBattery System will contribute to the promotion of modal shift*, as it can be used in a variety of transportation modes, including rail, land, air, and sea.

*Modal shift: Converting cargo transportation carried out by vehicles such as trucks to the use of railways and ships, which have a lower environmental impact (Source: Ministry of Land, Infrastructure, Transport and Tourism “Logistics: What is Modal Shift”)

We believe that if we can achieve a modal shift and lower logistics costs through the popularization of the “IceBattery System,” we will be able to solve the problems faced by the low-temperature logistics industry, such as the high cost structure, lack of human resources, working environment problems, traffic congestion, and CO2 emissions. By working to build a new cold chain, we are taking on the big goal of realizing a decarbonized society and bringing enriched lives to people around the world.

3. Strategies for Business Success

◆ We develop solutions that support low-temperature logistics and temperature control, and also support customization

To cover end-to-end cryogenic logistics, we have developed solutions that accommodate various transportation methods and transportation distances.

We have obtained various patents for products developed in-house. In anticipation of expanding the global market, we have obtained patents not only in Japan but also overseas in the United States, China, Taiwan, and India. As the saying goes, “Those who control logistics control the world,” we believe that logistics is the key to expanding our domestic and international markets.

We can flexibly respond by customizing transportation equipment to suit the needs of business operators, including packaging products that incorporate “IceBattery” into transportation equipment such as 20-foot containers and compact cold storage boxes. In addition to purchasing, we also support rental and leasing transactions to keep the initial investment at the time of introduction low.

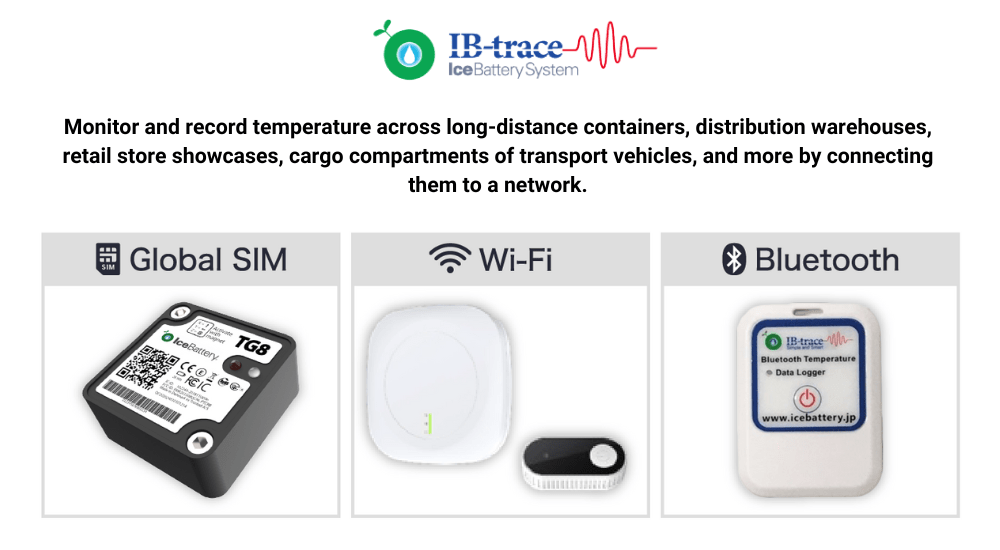

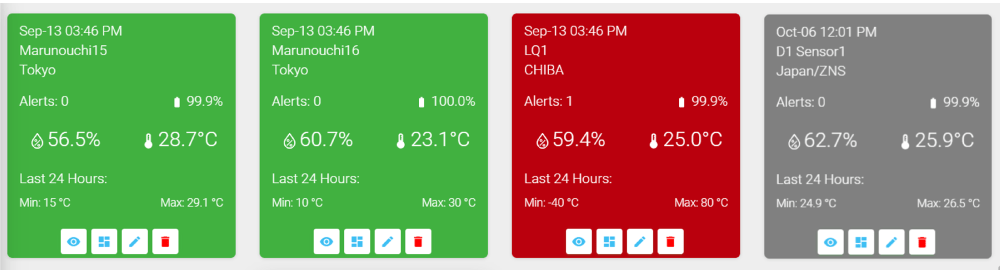

◆ An IoT Solution: Digital Connectivity for Analog Hardware

Up until now, our company has developed the analog hardware “IceBattery”, and built the “IceBattery” into a container or special cold storage box to suit the user’s application, and provided the “Ice Battery” ready for immediate operation. We have been working on “Battery System” solutions, and since 2021 we have implemented “IB-trace”, an IoT solution that can monitor the delivery status and temperature of pharmaceuticals, food, etc. by implementing digital technology on this analog technology.

“IB-trace” has three types of services: Global(Sim) / Wireless (WiFi) / BLE(Bluetooth).

– Global

This is a system that integrates IoT sensors and global SIMs to monitor 12 parameters such as location information, temperature measurement, opening/closing of cold storage boxes, and shock detection from a customer-specific screen during long-distance transportation on a global scale.

– Wireless

This system uses temperature sensors connected to the gateway to manage and track temperature changes in limited ranges where Wi-Fi radio waves can reach, such as distribution warehouses and retail stores’ frozen and refrigerated showcases. The real-time status of the temperature sensor is displayed on a dedicated screen, and you can also check it from your smartphone.

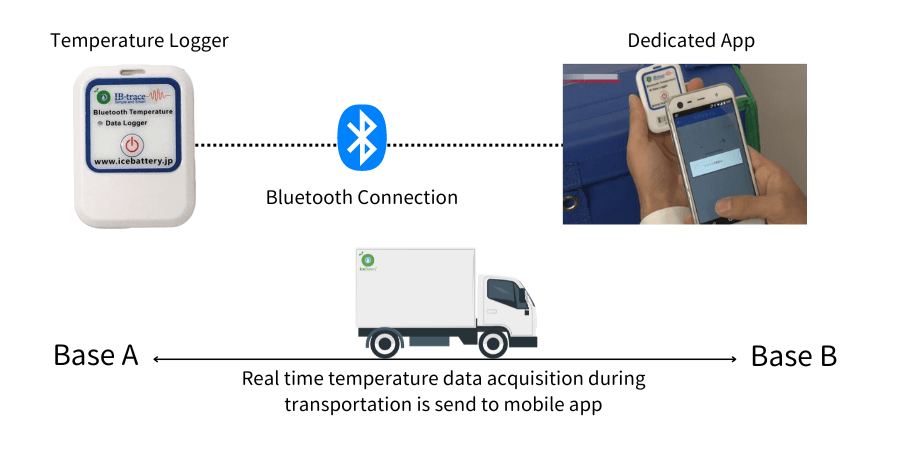

– Bluetooth

This is a system that allows you to connect a temperature logger to a smartphone via Bluetooth and check the temperature inside the cargo compartment of a transport vehicle in real time from a dedicated app.

◆ Expanding the Global Cold Chain: Introducing the IceBattery System and IoT Solution

By implementing a temperature sensor connected to a network on the analog hardware “IceBattery”, it is now possible to constantly monitor the location information and temperature of transported goods as they move around the world. Because this solution saves logs on the server and allows you to check the data from a web browser, we believe it will also contribute to lowering the hurdles to implementing traceability* for food and pharmaceutical products, which requires time and effort to organize and store records.

*Traceability: Individually identifying products and their raw materials, making the process from production to processing, distribution, sales, and disposal traceable.

The global market size for food traceability is expected to grow from USD 14.5 billion in 2021 to USD 28.1 billion by 2030. The market is driven by an increase in demand for safe food products due to the spread of the new coronavirus, and analysis shows that this trend is particularly strong in the Asia-Pacific region*.

*REPORT OCEAN『FOOD TRACEABILITY MARKET SIZE, SHARE & TRENDS ANALYSIS – GLOBAL OPPORTUNITY ANALYSIS AND INDUSTRY FORECAST 2030』

We believe that our cold chain solution, which supports end-to-end globalization, is extremely effective in meeting global traceability needs.

4. Future Business Growth

◆ Capturing Japan’s Cold Chain Market with an Alternative to Refrigerated Trucks and Dry Ice

We have established transactions with major land, sea, and air players in domestic logistics, and each company has begun putting the “Ice Battery System” into practical use. Currently, it is only used as a means of transportation, but we aim to expand its range of use by demonstrating its effectiveness in cost reduction and low-temperature logistics at various companies.

Currently, we are promoting the switch from dry ice to domestic companies, proposing the use of “IceBattery” insulated boxes using room-temperature vehicles to pharmaceutical and food logistics and wholesalers, and conducting demonstration experiments on mixed loading in multiple temperature zones. We plan to cover the Japanese cold chain market and expand our business not only to less developed cold chain countries but also to developed countries such as the United States.

We believe that the need for energy conservation in cold chains is accelerating not only due to global environmental issues but also due to the recent rise in energy and electricity costs. Using the knowledge we have cultivated over the years, we are also focusing on introducing technologies to the market that aim to reduce electricity bills by 50-70%.

The size of the cold chain market in fiscal 2020 is approximately 1.75 trillion yen*1 in Japan, while the global market size is estimated to be approximately 20.95 trillion yen*2. We plan to proactively develop this strategy.

*1 Source: Yano Research Institute “Conducting a survey on the low-temperature logistics market (2021)”

*2 Source: Allied Market Research “Cold Chain Logistics Market 2022”

Foreign exchange rates from December 27, 2020 to January 2, 2021, based on the foreign exchange rates specified by the Ministry of Finance Ordinance as stipulated in Article 4-7 of the Customs Tariff Act. Converted at 1 dollar = 103.65 yen

◆ Expanding into the Indian Market through Partnership with a Leading Container Shipping Company

In October 2019, we signed a partnership agreement with a major container shipping company in India. We have already delivered “Ice Battery” carts and 20-foot containers and completed multiple transportation tests. Using this as a starting point, we aim to promote cold chain development in India.

In the future, we plan to enter the country’s market in earnest and expand our business. While India is one of the world’s leading producers of agricultural products and dairy products, low-temperature logistics is not widely used, so food loss, which results from crops being discarded during the distribution process, is a problem. Our company hopes to contribute to the elimination of food waste in the country with the Ice Battery and serve as a role model for building cold chains in emerging countries.

◆ Bringing Electric Vehicles with IceBattery Technology to Market and Global Expansion

In May 2022, we jointly developed an electric vehicle for pharmaceutical delivery equipped with an IceBattery in collaboration with pharmaceutical wholesaler Alfresa Co., Ltd., and began demonstration experiments.

Refrigerated vehicles normally require the operation of a compressor, so it was thought to be unrealistic to develop refrigerated vehicles using electric vehicles due to fuel efficiency issues. However, if electric vehicles equipped with IceBattery are put into practical use, long-distance transportation of over 300 kilometers will become possible, making it possible to achieve last-mile delivery with a low environmental impact. Based on this track record, the number of electric vehicles equipped with ice batteries is expected to expand in the global market.

Furthermore, we are developing a system that simultaneously freezes the “IceBattery” when charging a vehicle using an external power source, and maintains the vehicle’s luggage compartment at the optimal temperature without using electricity even after the external power source is turned off.

◆ Enhancing Business Expansion Through Product Development for General Consumers

Currently, our main business is developing solutions targeting logistics, transportation services, food-related, and medical-related businesses, but we also plan and develop products for general consumers. In addition to products developed in-house, we also develop products jointly with manufacturers, which are sold through distributors and manufacturers on major e-commerce sites as well as physical stores such as sporting goods stores and home centers.

Among products for general consumers, “IceBattery Fresh” has been featured in many media outlets as a product to prevent heatstroke in the summer and to alleviate symptoms of side effects from vaccination, and awareness among general consumers is also expanding. A wide variety of products have already been introduced to the market to help overcome the summer heat, which is becoming more severe year by year. However, due to recent price increases and concerns about energy supply, there is a market for products that can be used repeatedly and have a low environmental impact. We believe there is plenty of room for entry.

In the future, we will focus on planning and developing products for general consumers, and aim to expand our business by expanding the industries in which we can collaborate.

◆ Milestone: Future Exit Strategy Envisions IPO

The table below shows the current schedule assuming future management progresses according to the business plan. Therefore, please note that the schedule may change depending on the success or failure of this fundraising and the amount raised. Furthermore, sales figures are based on the business plan and are the issuer’s forecasts, so they do not guarantee future stock prices or IPOs, etc.

We are currently receiving feedback from many customers (in the logistics, food, and pharmaceutical industries), such as “I want to switch from dry ice to ice batteries” and “I want to build a low-temperature transportation system that does not use frozen/refrigerated vehicles.”

Our company has originally operated with the motto of realizing an environmentally friendly cold chain that does not emit CO2. Currently, many companies are becoming more aware of environmental conservation and SDGs, which has finally given them a tailwind. Riding this tailwind, we are working to expand the domestic market by providing alternative solutions to dry ice, and by focusing on popularizing and promoting modal shifts.

In India, the cold chain is not well developed and fresh produce is easily perishable as agricultural products are transported at room temperature, leading to a lot of food loss. With a major Indian container shipping company adopting Ice Battery 20ft/40ft containers starting in 2022, demand is expected to increase not only from the food industry but also from the pharmaceutical industry. Currently, ice battery containers are being introduced in some parts of India, but from 2022 to 2023, we aim to further increase the number of containers and eventually introduce ice battery containers to terminals across India.

We aim to utilize the track record of introduction in India during 2023 and use this as a business model to spread it to Asia and Europe.

In the cold chain, especially in the pharmaceutical transportation industry, proven track record and reliability are key. By safely transporting pharmaceuticals and food in India, where power outages are common and infrastructure facilities are poorly developed in some areas, we believe that this track record will serve as a basis for companies’ decisions to introduce the system.

5. Team and Founding Journey

As a global company, we are a passionate family, embracing each individual’s unique strengths to tackle new challenges continuously.

ITE Co., Ltd is a small and elite company with six employees including the president, and is engaged in the development and verification of Realtech (research and development-based innovative technology) products, domestic sales consulting, accounting, customer support, and overseas transactions. This team is made up of members with a wide variety of backgrounds, including civil servants, IT, sales, and aviation, and they utilize their individual personalities to carry out their daily work. Unlike large companies, work is not divided into departments and each department is specialized in its own work, but each individual is required to respond flexibly and without bias. Each member embraces any role and shares a commitment to advancing the company, which has enabled ITE Corporation to thrive for 15 years.

◆ Team

-

Pankaj Garg

Pankaj Garg -

Jerry Tsai

Jerry Tsai -

John Anton

John Anton -

Vivek Sharma

Vivek Sharma -

Kenki Nagaya

Kenki Nagaya

Representative Director & CEO

Born into a family of businessmen in India, he specializes in manufacturing in the semiconductor field and holds numerous patents. He was fascinated by Japanese manufacturing, and after coming to Japan as an engineer at Kobe Steel, Ltd. in 1988, he worked at Intel Corporation before establishing ITI Corporation in 2007. He focused on improving the cold chain of medical and food products, and at the same time, with an awareness of environmental issues, he established an “environment friendly” low-temperature logistics system” that can be used repeatedly and does not require electricity during transportation. He believes that there is value in daring to try “what no one else can do” and “what no one else does,” and he is proud that he has the talent to create something that doesn’t exist in the world yet. He aims to contribute to the development of Japanese agriculture by leveraging the “IceBattery” to become a bridge between Japan and India, and by expanding Japanese agricultural products overseas. He also has Japanese permanent resident status and has lived in Japan for 30 years.

Management/operation results

Global business development / Sales and marketing / Project manager / Technical support / Product planning and design / Overseas market strategy related / System memory / Product strategy planning / Intel platform management design, etc.

Development results

Artificial intelligence (AI)/robotics related development results

Language translation / voice transcription / unmanned new transportation system / automatic speed enforcement device / license plate reading / image processing/authentication / face/fingerprint recognition / computer vision* / expert system for unmanned space probe research and development research institute*, etc.

*Computer Vision: A field of artificial intelligence that gives computers the functionality of the human eye, allowing them to identify and understand objects and people in still images and videos.

*Expert system: A computer system that has specialized knowledge in a specific area and can make decisions and solve problems on a par with human experts.

Semiconductor-related/OS/device driver-related development/design results

2D, 3D graphics device driver / DOS for Windows 95, NT, BIOS / Various OS that make up Windows NT, XP (touch panel PC for computers / printer driver / flash memory / 2D / 3D graphics) / Mobile information terminal OS design / Notes PC (power management, coolant design), etc.

Director

Managing Director. He has 15 years of experience in sales, marketing and business development of hardware products in the consumer electronics and semiconductor fields. He currently works as a product sales manager at Meiloon Industrial Co., Ltd. in Taiwan. He makes the world’s first entry into the home appliance industry market with his 5.1ch wireless speaker system. Obtained Bachelor of Science (process manufacturing engineering and management skills). He received his MBA from Yuan Ze University in Taiwan.

In 2007, joined ITE Co., Ltd.

Director

He has a long career in technology, including five years as vice president at Applied Materials, Inc. in the United States. He also lived in Shanghai for three years as the leader of the overseas sales department of Energy & Environmental Solutions Group. Prior to Applied Materials, he worked at Intel Corporation in the US for 22 years. He was in charge of the Asia-Pacific region, and was responsible for managing sales and markets in Asia, which accounts for about half of Intel’s profits. He also served as president of Intel Corporation (Japanese corporation).

In 2019, participated in ITE Co., Ltd.

Director

After working for Intel in the semiconductor field for 26 years, he joined ITI Corporation. He has extensive experience spanning multiple continents, leading global, cross-functional groups in diverse areas such as engineering, long-term demand forecasting, capacity planning, and product pricing. , was responsible for managing the goals. During his overseas assignment, he gained experience not only in sales and marketing in the customer, IoT, and data center segments, but also in regional business operations management. He also earned a master’s degree in computer engineering.

In 2019, participated in ITE Co., Ltd.

Executive Officer and Sales Planning

Graduated from the University of Manchester, UK in 1987 and joined Hitachi, Ltd. At Hitachi, Ltd., I worked in the information and communications department for 30 years, gaining experience in information product development, product planning, and overseas sales.I worked with domestic and foreign stakeholders to provide information to the Fortune Global 500 (500 major companies in the world). We provided a number of products.

I received my Master of Business Administration (MBA) from Temple University Japan Campus in 2012. There, I met Garg, my senior MBA student, and I got the impression that the passionate dreams of entrepreneurs are budding in Japan as well.

We have decided to join Team Garg so that we can provide the wisdom of “information” products to “food and medical products” that are distributed around the world.

In 2022, participates in ITE Co., Ltd.

◆ Motivation Behind Founding ITE

“I want to save mothers all over the world. I want to help children.” With his childhood experience in mind, he traveled from India and Japan to the world. Cold chain revolution with “Ice Battery

During my tenure at Intel Corporation, my focus was on developing advanced PC coolants. However, I gradually realized the potential for these coolants to address critical issues in global low-temperature logistics. Motivated by this insight, I made the decision to depart from the company. In 2007, I took the leap and established ITE Co., Ltd.

My journey was deeply influenced by the stark realities of my upbringing in India. From a young age, I witnessed the devastating consequences of inadequate access to essential resources like vaccines and food. I saw children perish and mothers weep, burdened with grief that would last a lifetime. Determined to prevent such suffering, I pledged to dedicate my life to combating infectious diseases and other health challenges. Though my initial aspiration was to become a doctor, I relinquished this dream to my brother, opting instead to pursue a path in engineering.

Guided by the mantra, “Life is for people,” I constantly challenge myself with the question, “How can I make a meaningful impact on our planet within my lifetime?” Every day, we at ITI Co., Ltd. strive to pioneer a revolution in low-temperature logistics. Our mission is to develop innovative systems that ensure the safe transportation of vaccines and food, safeguarding the lives and futures of generations to come.

◆ Mentor’s Evaluation

◆ Media Coverage

- Fuji Television|Live News It! (July 27, 2022)

- NHK Osaka Broadcasting Station | Domestic News (June 28, 2022)

- Nikkei Shimbun | Environmentally friendly pharmaceutical delivery (May 20, 2022)

- NHK WORLD-JAPAN|Direct Talk (November 19, 2021)

- Nikkei Shimbun | 12-hour cold storage without power supply (March 16, 2021)

- TV Tokyo | World Business Satellite (February 2, 2021)

- TBS TV|news23 (November 25, 2020)

- TV Tokyo | SDGs File Change the World (October 21, 2020)

- NHK WORLD-JAPAN|BIZ STREAM (July 13, 2020)

- BS-TBS|Key of Dreams (May 20, 2020)

- TBS TV|Gacchiri Monday! ! (February 2, 2020)

6. Benefits for Stock Acquisition Rights Holders

◆ We deliver “IceBattery” products for general consumers

We would like to express our gratitude to all stock acquisition rights holders for their support, and we would like to provide a special benefit service for stock acquisition rights holders to deepen their understanding of our products and allow more people to use “IceBattery.” We provide. Please check here for details.

Reference Date For Benefits

The last day of March every year

Special Benefits

- 44 stock acquisition rights or less : Ice Battery Fresh x 1

- Stock acquisition rights 45-90 : Ice Battery Fresh x 5

- 91 or more stock acquisition rights : Ice Battery Fresh x 10

How To Apply

After the reference date has passed, we will inform you that you can apply. At that time, please let us know by emailing us (info@ithrue.com) that you would like to use the Stock Acquisition Rights Holder Benefits System and the product you would like.

We will confirm your use by comparing the name and address you provided at the time of application with the name and address on the list of stock acquisition rights holders. If there is a change in your name or address on the list of stock acquisition rights holders, please complete the necessary procedures before applying.

Note

- This benefit is limited to one per person per year.

- Benefits are subject to change in the future.